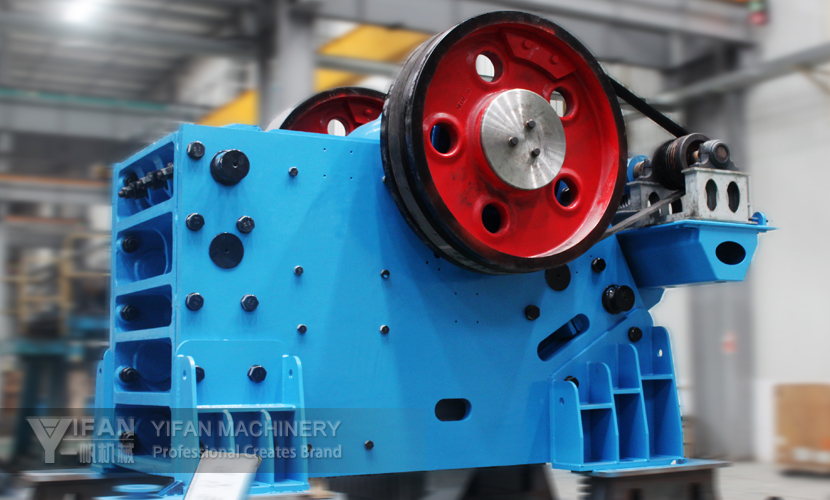

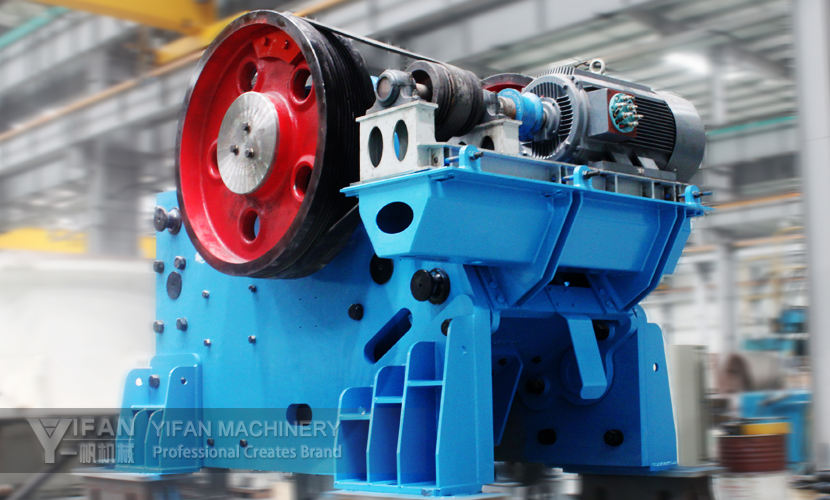

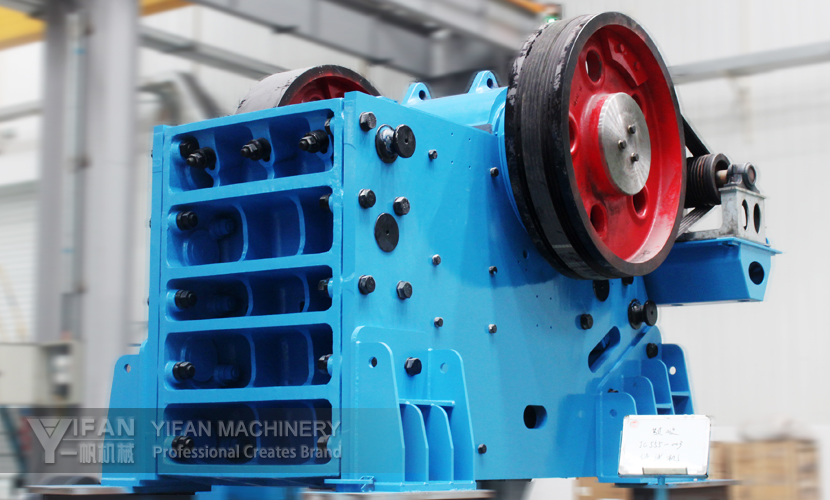

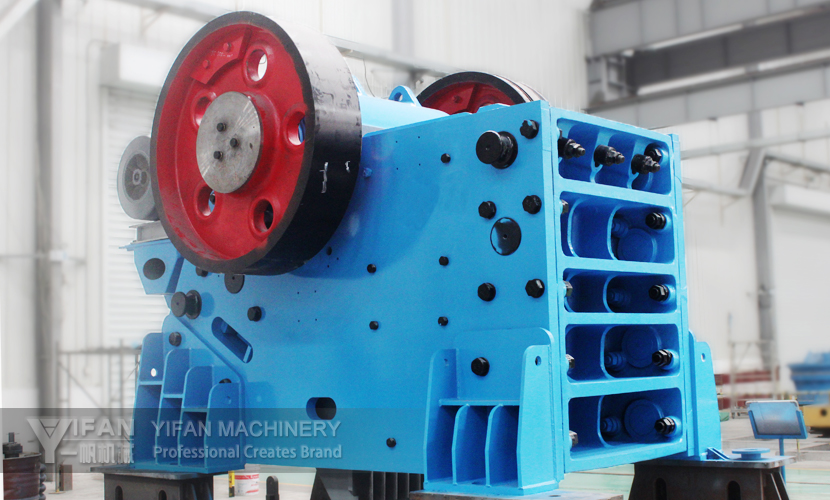

Type:Primary crusher Feed Size:425mm-1250mm

Capacity:50-2700t/h

Materials:River stone, gravel, granite, basalt, minerals, quartz, dolerite, etc.

Applications:Mining, metallurgy, construction, highway, railroad, water conservancy, etc.

1. The chassis of JC jaw crusher adopts welding type and assembly type. Welding type is characterized by impact resistant, uniform stress and low failure rate. Assembly type is suitable for construction sites with transportation difficulties.

2. Symmetrical V cavity design can enlarge material size, improve production capacity and lower plate wear.

3. Centralized lubricating system can protect bearing grease from being polluted and make lubrication process more convenient.

4. JC jaw crusher is fixed by appropriative rubber damping device to lower the shock to foundation through absorbing device vibratory force.

|

Model

|

Size Of Feed Opening

(mm)

|

Discharge Range

(㎜)

|

Capacity

(t/h)

|

Motor power

(kW)

|

|

JC231

|

510X800

|

40-150

|

50-250

|

55-75

|

|

JC337

|

580X930

|

50-160

|

75-265

|

75-90

|

|

JC340

|

600X1060

|

60-175

|

85-300

|

75-90

|

|

JC3540

|

650X1060

|

110-225

|

120-400

|

75-90

|

|

JC442

|

700X1060

|

70-150

|

120-380

|

90-110

|

|

JC440

|

760X1020

|

70-200

|

120-520

|

90-132

|

|

JC443

|

850X1100

|

80-215

|

190-670

|

132-160

|

|

JC549

|

950X1250

|

110-250

|

315-845

|

160-200

|

|

JC549(Ⅱ)

|

1000X1250

|

160-300

|

480-1105

|

160-200

|

|

JC5149

|

1050X1250

|

210-350

|

650-1310

|

160-200

|

|

JC555

|

1070X1400

|

125-250

|

385-945

|

160-220

|

|

JC5155

|

1170X1400

|

225-350

|

755-1425

|

160-220

|

|

JC649

|

1100X1250

|

125-300

|

400-1065

|

160-200

|

|

JC659

|

1200X1500

|

150-350

|

460-1300

|

200-250

|

|

JC663

|

1200X1600

|

150-350

|

520-1475

|

250-355

|

|

JC759

|

1300X1500

|

150-350

|

480-1300

|

200-315

|

|

JC771

|

1500X1800

|

150-350

|

590-1800

|

315-400

|

|

JC771(Ⅱ)

|

1500X1800

|

150-400

|

590-2100

|

315-400

|

|

JC783

|

1500X2100

|

175-450

|

760-2700

|

400-500

|

Note:The crusher capacities listed are based on instantaneous sampling of medium hardness rocks. The above data is for reference only, please contact our engineers for equipment selection for specific projects. The crusher output shown in the above figures is based on crushing medium fragile rocks with an average specific gravity of 2.7t/m³, when the feed materials enter the crushing chamber smoothly without bridging and blocking. The small value is taken when the feed materials are not smaller than the discharge port. The large value is taken when the fine materials are included in the feed materials. The output may vary with the feeding method and material nature such as grain size composition, water and mud content, bulk density and friability.

Capacity: 100t/h Materials: Basalt

Applications: Building aggregate production line

Main equipment: PP900 mobile jaw crushing plant, PP120 mobile cone crushing plant

Tips:Depending on the process requirements, the combination of various types ofequipment to meet customer's different process requirements.

Capacity: 250t/h Materials: Granite

Applications: Road and building construction

Main equipment: PP1060 Portable Jaw Crusher

Tips:Depending on the process requirements, the combination of various types ofequipment to meet customer's different process requirements.

Capacity: 200t/h Materials: Granite

Applications: Road and building construction

Main equipment: ZSW4911 Vibrating Feeder、PE-750*1060 Jaw crusher、CCH651C Hydraulic Cone Crusher、2YK1860 Inclined Vibrating Screen、2YK216

Tips:Depending on the process requirements, the combination of various types ofequipment to meet customer's different process requirements.

Capacity: 200 t/h Materials: granite stone

Applications: Road and building construction

Main equipment: PP1060 Jaw Crusher, PP250SMHS Cone Crusher, Etc;

Tips:Depending on the process requirements, the combination of various types ofequipment to meet customer's different process requirements.

Copyright (c) 2023 Zhengzhou YiFan Machinery Co.,Ltd All rights reserved.

TEL: +86-371-64628852 FAX: +86-371-64628872 E-MAIL:info@yfmac.com